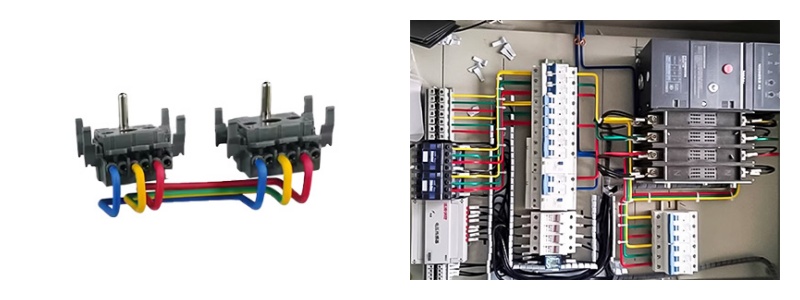

ESC-BZ30-3D wire cut strip 3D bending machine is operated by 7-inch touch screen. The machine uses electric bending and digitally adjusted bending methods to make the operation and bending process more accurate and efficient. 8-wheel drive, optional servo feeding ensures the machine is stable and sturdy, while taking into account the easy operation of feeding. The cable is fed by belt, with no embossing or scratching on the cable, and the front end has a peeling and pressing function to ensure high quality and efficiency of the product. This machine uses high-quality imported high-speed steel to ensure the durability of the machine.

Overall, the ESC-BZ30-3D Wire Cutting Stripping 3D Bending Machine is an excellent machine that saves time and increases productivity. Its innovative properties make it ideal for wire and cable manufacturers looking to streamline their production processes.

feature:

Optional: MES system, Internet of Things system, fixed-point coding function, intermediate peeling function, external auxiliary equipment alarm;

User-friendly system: intuitive operation via 7” color touch screen;

Modular interface: convenient for linking accessories and peripheral equipment;

Modular design: can be upgraded in the future;

Various add-on options: Customizable system. Special cable processing, non-standard customization is available.

| Model | ESC-BZ30-3D |

| Processing range | 0.75-30 mm2 |

| Cutting length | 1-99999.99mm |

| Max Guide Tube diameter | 14mm |

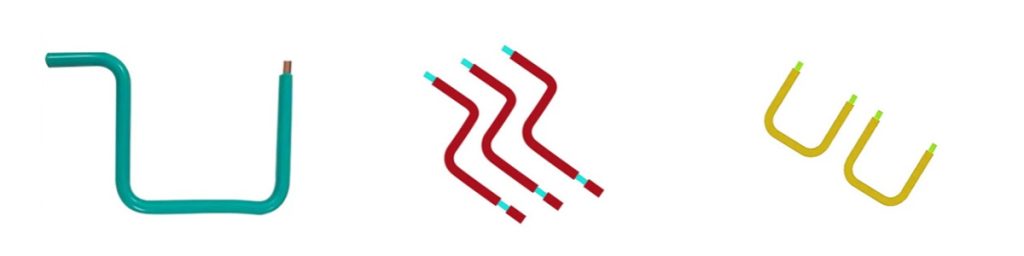

| Bending method | Electric bending, digital adjustment |

| Bend direction | X+/X-,Y+/Y- ,Z+/Z- |

| Speed | 1000 PCS/hour (according to the length and size of the wire) |

| Minimum stripping length | Total length--left stripping length--right stripping length >70mm |

| Dimensions (L x W x H) | 600X480X550 mm |

| Weight | 120kg |

| Electrical connection | 220V 50/60HZ |

| wire type | Single core wire |

| Air source | 0.5Mpa-0.85Mpa clean air source |